Rapid Prototype Plastic Injection Mold Designer for Home Video Accessories Set

Package Size 350.00cm * 100.00cm * 10.00cm Package Gross Weight 350.000kg The Structure of Plastic Injection MoldThe bas;

Basic Info.

| Model NO. | C-17 |

| Mould Cavity | Single Cavity |

| Plastic Material | ABS |

| Process Combination Type | Single-Process Mode |

| Application | Household Appliances, Furniture, Commodity, Electronic, Home Use |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | CE, ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 3 Years |

| Transport Package | Customized or Color Box |

| Specification | 350*100*10 |

| Trademark | OEM |

| Origin | China |

| HS Code | 3901100001 |

| Production Capacity | 500set/Years |

Packaging & Delivery

Package Size 350.00cm * 100.00cm * 10.00cm Package Gross Weight 350.000kgProduct Description

| Part 1: Mould Description | |

| Company Name | Powerfulsky Mould Co.,Ltd |

| Business Type | Manufacturing |

| Shaping Mode | Plastic Household Injection Mould |

| Products Name | Plastic Injection Electronics Accessories Mold |

| Mould Life | According to client's requirements |

| Mould base Standard | HASCO, DME, LKM, Meusburger, FUTABA, etc |

| Core & Cavity Material | 718H, P20, NAK80, S316H, SKD61, 1.2311, 1.2343, etc |

| Products Material | PP, PA6, PLA, ABS, PE, PC, POM, PVC, PET, PS, TPE etc |

| Design Software | UG, PROE, Auto CAD, Solidworks |

| Runner Type | Hot runner or cold runner |

| Gate Type | Side gate, Sub gate, Pin point Gate |

| Surface Treatment | Polish,Texture, Silk-screen printing,Anodizing,etc |

| Equipment | CNC,EDM,Milling,Grinding,Wire Cut,Plastic injection machine |

| Package | Wooden box for mould, carton for plastic products |

| Lead Time | 25-40 days for T1 |

| OEM/ODM Service | Available |

| Part 2: Mould Making Process | |

| Quotation | Need 2D/3D drawing or Samples |

| Mould Design | Mould design drawing could be sent for confirmation |

| Mould Making | Start mould manufacturing after the mould design is confirmed |

| Mould Trial | 1st shot samples will be available for checking |

| Sample Confirmation | Customer to check and confirm samples |

| Mould Modification | Modify the mould if necessary |

| Mould Delivery | To deliver the mould after received the 3rd payment |

| After-Sales Service | Free of charge for 12 months warranty |

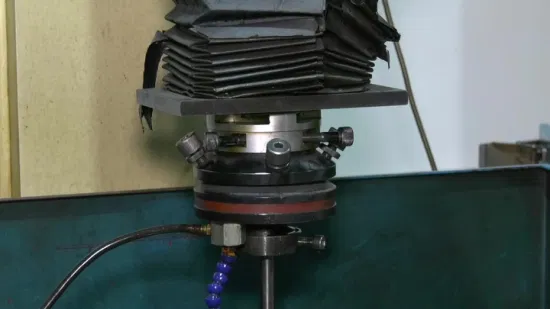

The Structure of Plastic Injection MoldThe basic structure of plastic injection mold is composed of two parts: fixed mold and movable mold.The fixed mold part is installed on the fixed plate of the injection molding machine,and the movable mold part is installed on the mobile board of the injection molding machine.During injection molding,the fixed part and the hydraulic pressure.The driven movable mold part is guided and closed by the guide column,and the plastic melt is injected from the injection molding machine.The nozzle of the machine enters the cavity through the mold gating system;the injection molding is opened after cooling.The mold,that is,the fixed mold and the movable mold are separated.Generally,the plastic parts remain on the movable mold.The mold ejection mechanism pushes the plastic parts out of the mold.According to the different functions of each part on the mold,the general injection mold can be made of the following composed of several parts.1.Molded PartsSpecify the parts that make up the cavity in the mold and movable mold parts.It is usually composed of a core,a die,an insert,etc.,and the cavity is formed when the mold is closed.Due to the filling of the plastic ment,it determines the shape and size of the plastic part.2.Gating SystemThe gating system is the channel through which molten plastic flows from the injection molding machine nozzle into the mold cavity.It consists of a main runner,a branch runner gate and a cold well.3.Guiding MechanismThe guiding mechanism is divided into two categories: the guiding mechanism between the movable mold and the fixed mold and the guiding mechanism of the ejecting mechanism.The first is to ensure that the movable mold and the fixed mold are accurately aligned when the mold is closed,so as to ensure the accuracy of the shape and size of the plastic part;the latter is set to avoid the skew of the push-out plate during the ejection process.4.Release MechanismThe device used to eject the plastic parts from the mold when the mold is opened,also known as the ejector mechanism.There are many structural forms,and the common ones are ejector ejection mechanism,push plate ejection mechanism and push tube ejection mechanism.5.Lateral Parting and Corn Pulling MechanismWhen there are concave-convex shaped holes or bosses on the side of the plastic part,a lateral punch or core is required to form.Before the mold is opened and the plastic part is pushed out,the lateral punch or the lateral core must be pulled out or pulled out from the plastic part,so that the plastic part can be demolded smoothly.The mechanism that moves the lateral punch or the lateral core is called the alteral core-pullig mechanism.6.Heating and Cooling SystemIn order to meet the temperature requirements of the injection molding process for the mold,the mold temperature must be controlled,so the mold is often equipped with a cooling system and heating elements are installed in or around the mold.The cooling system generally opens cooling water channels on the mold.7.Exhaust SystemIn the injection molding process,in order to discharge the air in the cavity,it is often necessary to open an exhaust system,usually a number of grooves are purposely opened on the parting surface,or the push rod of the mold or the core and the template are used.Exhaust through the matching gap between them.The exhaust volume of small plastic parts is not large,so it can be directly exhausted by parting without having to set up an exhaust groove.8.Other PartsFor example,it is used to fix and support forming parts or parts that play the role of positioning and limiting.

PowerfulSky Mould is specializes in the production of TV Shell molds,provides gas-assisted molding injection mold solutions,short delivery times,and standardized TV mold design and processing.

FAQQ: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry.If it is veryUrgent,please call us or tell us in your email so that we will regard your Inquiry as priority

Q:How long is the lead time for mold?

A:It depends on the mold's size and complexity.Normally,the lead timeIs 25~35 days.If the olds are very simple and not in big size,we can work out with 10 days

Q:Will my drawings be safe after sending to you?

A:Yes,we will keep them well and not release to the third party without your permission

Q:How to respond quickly to products?

A:If you contact us by email,Wechat,Whatsapp,we promise to reply you within 8 hours.OEM/ODMIf you ...1. Are looking for OEM/ODM manufacturers in this industry.2. Need someone that can produce what you want and have a custom design printed to your specification.Then our OEM/ODM service is for you!

You may also like

Send inquiry

Send now