OEM Plastic Injection Mould for Electric Hair Drier

OEM Plastic Injection Mould for Electric Hair Drier About usGreen Vitality was established in 1993 with 16 employees. Wi;

Basic Info.

| Model NO. | GV-mold-0037 |

| Application | Household Appliances |

| Runner | Cold Runner |

| Design Software | AutoCAD |

| Installation | Fixed |

| Certification | ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 3 Years |

| Transport Package | Plywood Case |

| Specification | customized |

| Trademark | GV |

| Origin | Guangdong, China |

| HS Code | 84807100 |

| Production Capacity | 500sets Per Year |

Product Description

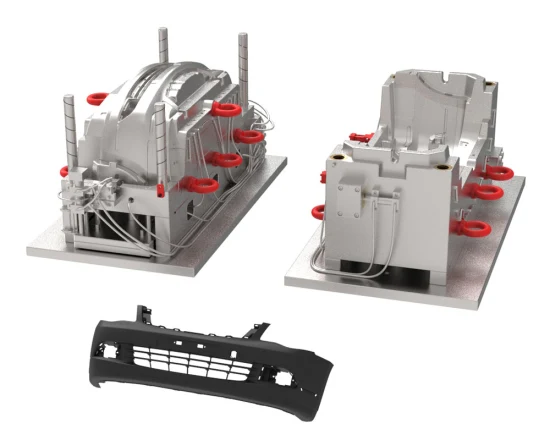

OEM Plastic Injection Mould for Electric Hair Drier

| Items | Injection plastic mold |

| Parts materials | PC, ABS (also other material like PP, PBT, BMC, PMMA, PC+ABS, PP+TD20%, PU, PE, PVC) |

| Mold base steel | NAK80, S136, SKD61,45, S55C, P20, 1730, 2738, 718h, H13, BPMHH, 2343ESR |

| Core and cavity steel | NAK80, S136, SKD61, P20,1730hh, 2738hh, 718h, H13, BPMHH, 2343hh |

| Injection system | Edge gate, slid gate, sub gate, direct gate, pin point gate, valve gate |

| Mould standard | DME, LKM, HASCO |

| Cavity numbers | Single or multi (customized up to 32C AV) |

| Runner | Hot or cold |

| Injection machine | 100-1500T |

| Cycle time | 10-120 seconds |

| Mold of steel suppliers | Finkl, Assab, Daidao, LKM, Buderus |

| Hot runners suppliers | Synventive, Yudo, Incoe, Hasco, DME, Moldmaster, HRS, Delachaux |

| Mould life | 300,000 - 1,000,000 shots |

| Tooling lead-time | 15-40 days depends on qty and complexity of mold |

| Design software | Pro/E, UG, Catia, Solidwork, Moldflow, AutoCad |

| Mould life | 300,000-1,000,000 shots |

| Shipping packing | Wooden case or according to customer's requirements |

| Certificate | ISO |

About usGreen Vitality was established in 1993 with 16 employees. With the development of our company for almost 30 years, we have become a reliable supplier as well as the strategic partner of customers worldwide for providing the most efficient solutions for their applications. We will continue the mission to be a world-class expert in mold making industry.

- High quality with cost-saving designOur engineers with over 15 years' experience would design the plastic injection molds with the most reasonable design.

- Commitment to Quality & Competitive PriceWith diversity in equipment capabilities and in-depth knowledge about industrial injection mold, Green Vitality is able to offer Competitive Price for all products and services reasonably.

- Delivery on time within budget We help customers control costs, create and execute the most efficient schedule for each project, taking full advantage of our supply chain network and mold processing and injection molding capabilities.

- High quality service At Green Vitality, the fast-response service is just the basic requirement, professional and efficient are our strength!

- One-stop service provider Technical support from the initial product design to the entire stage of mold making and product production and delivery.

Green Vitality is a long-standing mold maker with ISO9001 Certificated & over 30 years' export molds experience. We can customize injection molds include auto parts, electronic accessories, home appliances, daily necessities, medical component part and children toys and other customize plastic products.

Q1: Are you trading company or manufacturer?

A1: We are direct factory for making mould with experience more than 25 years.

Q2: Where is your factory located?

A2: Green Vitality is located in Shajing, Shenzhen City,Guangdong Province,China. 40 minutes from Bao 'an International Airport by car, 45 minutes from train station to our factory.

Q3: What we need for mould quote?

A: Usually we need the following information,

(1) Mould steel raw material you require or mould life you require.

(2) Mould cavity no. you want?

(3) 2D or 3D product drawing, or pictures with detail sizes information (length, width, height, thickness), or send samples directly to us.(4) Raw material of the product.

(5) Hot runner or cold runner, if hot runner which brand of hot runner you require.

Q4: How about quality control in your factory?

A: We believe "Quality comes before everything". We mainly do the following procedures:

(1) Design Optimize Control(2) Mould steel hardness Inspection

(3) Mould assembly Inspection.

(4) Mould trial samples inspection.

(5) Final inspection for mould & packing before shipment

Please send 3D/2D drawings or samples to us if you have any queries with regards to the above. Through streamlining the production of molds, we can help you cut cost up to 50%!

You may also like

Send inquiry

Send now